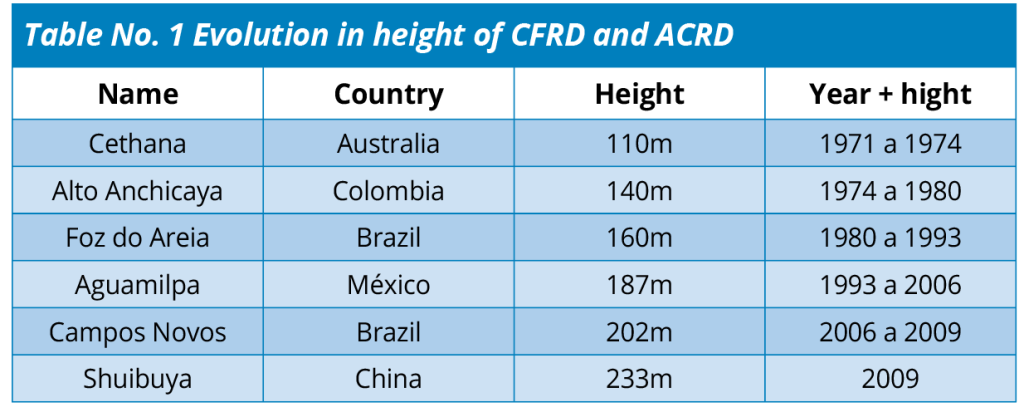

Across Australia, Colombia, Brazil, Mexico, and China, compacted rockfill dams began to evolve and grew in height over a short period, from 110m to concrete-faced structures approaching 300m high.

Table No. 1 presents the record of CFRD and Asphalt Core type dams built with compacted rockfill, indicating the years in which they were the highest dams in the world. All of these dams worked relatively well, with small leaks, except for Brazil’s Campos Novos Dam which had noticeable breaks.

At 202m high, Campos Novos was built with the following characteristics: L 592m; L/H 2.93; A/H2 2.60 – Basalt. The dam had a rapid lowering of the reservoir due to problems in the diversion tunnels, but this allowed us to see the arrangement of the central and lateral cracks that affected the slab.

Concrete faced rockfill dams

From 2000 to 2006, slab fractures also occurred at other CFRD type dams, including Tiangshengqiao (Tsq1). Built in China it was 178m high with the following characteristics: L 1104m; L/H = 6.2; A/H2 5.68.

This dam presented fractures in the central part which were repaired during lowering of the reservoir. When the reservoir was raised again, the same type of breakage could be observed, which was corrected using a compressible membrane that would mitigate the movement of the slabs, avoiding the transfer of forces that would break the slab. The treatment used worked relatively well. It should also be noted that the rockfill of this dam is made of limestone that tends to produce a well-graded rockfill with good compaction characteristics.

Other slab fractures also occurred at the 185m high Barra Grande Dam in Brazil. Built with the following characteristics: L -665m L/H 3.59; A/H2 3.16 – Basalt, it had breakage in the central compression joints, with high leaks.

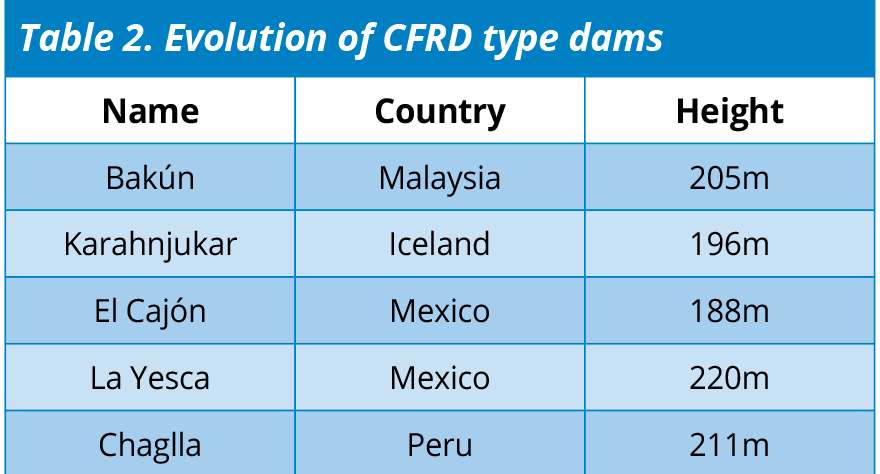

Table 2 identifies a group of CFRD type dams that were identified as possibly having problems with fracturing of the main slab and were studied and corrected to avoid breaks in the slab.

The Bakún dam slab was built in two stages. The lower stage 1 from the middle to the river bed and the upper stage 2 to the crown of the dam. Observations of the fractured dams indicated lower slab breaks and it was necessary to cut the lower joints of face 1 to introduce deformable wood that would mitigate the breakage of the slabs. The central joints were cut with a steel disc to introduce wood that mitigates the movements of the slabs and prevents their fracture. The top of the slab was built 10cm thicker and very well controlled and a high dam that could have had fractures in the slab was built without problems.

At the 196m high Karahnjukar Dam in Iceland the upper part of the left slab was built independently and in the central part similar recommendations that were recommended for Bakun were undertaken. The thickness of the slabs was increased, and compressible elements were placed in the central part that mitigated the potential movements of the central slabs.

Karahnjukar was built with basalt with high compressibility modules and its behaviour has been adequate.

Mexico’s La Yesca and El Cajón dams were built with compacted rockfill with high densities and excellent compressibility modules greater than 100 Mpa. This set of dams suffered variations in the design but the general behaviour, including the 233m Shuibuya dam in China, is proof that by adapting rapid non-conventional measures, it was possible to build the slabs without problems of excessive breaks.

At Chaglla Dam in Peru, the abutments of this 211m high dam were very steep but the rockfills were built with adequate specifications to obtain high capacities and low void ratios. Chaglla has performed well with no breakage of the main slab.

Recommendations

During decades of dam construction with compacted rockfill, it has been concluded that it’s feasible to design and build this type of CFRD and ACRD with heights close to 300m, with the following recommendations in mind:

- It is important that the rockfill be well graded with a uniformity coefficient Cu >12.

- Well graded rockfills are the best materials for producing adequate compacted rockfill. Cu =>12, high density, low void ratio, e < 0.22.

- If rockfill is not well graded (basalt) select heavier vibratory compactors > 20 t total weight and > 5t/m at the vibratory drum. Water addition to 200 l/m3

- Use thin layers (0.60m – 0.80m) for rockfill compaction in important zones (3A – 3B)

- Select internal and external water stops complemented with adequate mastics or fly ash to treat joints. (See Chaglla).

- Review dam stability and stresses using finite element numerical analysis to decide using compressible fillers in central joints