Rock-filled concrete (RFC) dams are constructed by pouring high-performance self-compacting concrete (HSCC) to fill the voids in preplaced large rocks. Invented in China, the RFC dam was developed to overcome temperature cracking which remains a problem for roller compacted concrete and the conventionally vibrated concrete dams. In a recent article by Feng Jin, Duruo Huang, Michel Lino and Hi Zhou, published in Engineering, the authors give an insight into the design, construction, and quality control of these structures.

Such an innovative use of large rocks in RFC dams has many advantages, and include:

- A reduction in cement consumption substantially lowers the hydration thermal increase and shrinkage of the concrete.

- Cooling pipes are no longer needed as temperature-control measures.

- Employing HSCC eliminates vibration or roller compaction in concrete placement. This simplifies the construction process, making RFC dams more economically profitable.

This simplifies the construction process, making RFC dams more economically profitable.

Evidence from projects has shown how the comprehensive unit price of an RFC dam is 10-30% lower than that of a conventional concrete or roller-compacted concrete dam. RFC also reduces carbon dioxide emissions by 72% in material production, 25% in transportation, 51% in construction, and 15.6% in the operation and maintenance stage.

“Given the crucial goals of energy conservation and emission reduction, the development of RFC has revolutionised construction technology,” the authors state, “fulfilling these goals by eliminating vibration or roller compaction and making full use of local materials.

Engineering efforts in RFC dams

To date, more than 130 RFC dams have been constructed and more than 30 RFC dams are under construction in China. These include the 69m high Baijia RFC double-curvature arch dam which was initially impounded in September 2015 and has been operating well for more than seven years.

An increasing number of high RFC dams have been completed, such as Xiyuan (77m high), Pingkeng (79.7m), Manping (77m), Maliuwan (75m), and Songlin (90m) RFC gravity dams, as well as the Baijia (69m), Shaqian (66m), and Niudongkou (64m) arch dams. In addition, the 83m high Yongfeng RFC arch dam is currently under construction.

RFC was also implemented in the reservoir dam for the Beijing 2022 Winter Olympics Games, to support the water supply for snowmaking in the alpine skiing events. In that project, the RFC pouring of a 58m high dam body was completed within only 140 days – a historically rapid construction for RFC dams.

ICOLD is supporting Chinese engineering efforts and is encouraging the development of RFC dams worldwide. A comprehensive technical standard system for RFC dams covering construction materials, design, construction, and quality control has been established, including the ICOLD bulletin No. 190 Cemented Material Dam: Design and Practice – Rock-filled Concrete Dam, which was formally approved in 2022.

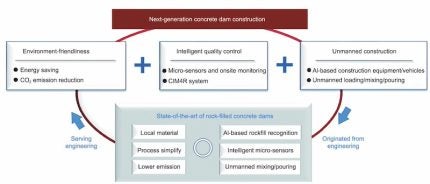

As the authors go on to comment, “sensitive and robust instruments to measure the workability of HSCC need to be continuously researched and developed”. They also name two fundamental scientific issues related to RFC that need to be addressed – pouring compactness and the effect of large rocks on the mechanical and physical properties of RFC. Furthermore, they discuss how intelligent or unmanned dam construction that adapts to the future labour market is a promising development direction, driving RFC technology to increase mechanical performance. There could also be a role for the adoption of AI-based construction equipment and vehicles, with unmanned vehicles being implemented to transport and place large rocks, while automatic mixing and pouring equipment for HSCC is currently under development.

As an emerging technology, the authors conclude that RFC dams “are continually contributing to the long-term, sustainable, and environmentally friendly development of dam construction in China and countries beyond”