Germany’s Fraunhofer Institute for Energy Economics and Energy System Technology IEE has developed an underwater energy storage system, that transfers the principle of pumped storage power plants to the seabed. After a successful field test with a smaller model in Lake Constance, the researchers are now preparing a test run off the Californian coast with its partners.

“Pumped storage power plants are particularly suitable for storing electricity for several hours to a few days. However, their expansion potential is severely limited worldwide and so we are transferring their functional principle to the seabed – the natural and ecological restrictions are far lower there. In addition” explains Dr Bernhard Ernst, Senior Project Manager at Fraunhofer IEE, “the acceptance of the citizens is likely to be significantly higher.”

The StEnSea (Stored Energy in Sea) project has been in development since 2012. Fraunhofer IEE is working with US start-up Sperra, which specialises in 3D concrete printing for applications in the field of renewable energies, along with Pleuger Industries. This German company, headquartered in Miami, manufactures underwater motor pumps, a key component of the StEnSea spherical storage. The partners have selected a coastal area off Long Beach near Los Angeles as the storage site and plan to put it into operation by the end of 2026 at the latest.

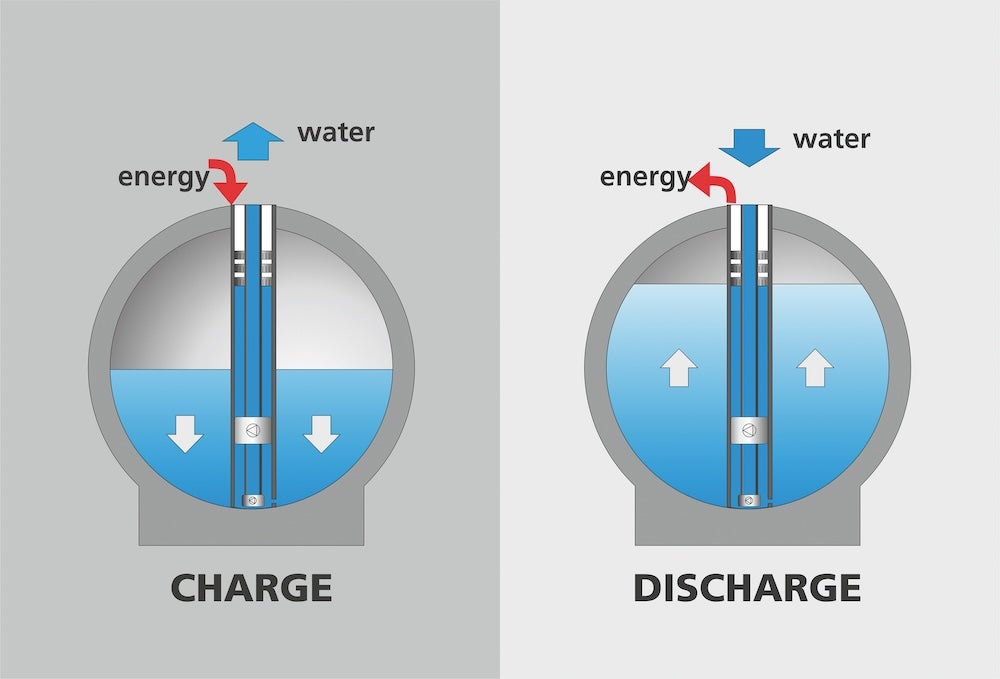

The StEnSea project will anchor a hollow, 400-ton concrete sphere with a diameter of 9m at a depth of 500-600m. By emptying the sphere, the storage is charged. When water flows in, electricity is generated, and it is discharged. The power of this prototype is 0.5MW with a capacity 0.4MWh.

Funding for the project is being provided by the German Federal Ministry for Economic Affairs and Climate Action, who is committing nearly €3.4 million, plus around US$4million from the US Department of Energy.

Sperra will manufacture the concrete sphere in Long Beach using a 3D printing process, possibly in combination with traditional concrete construction. It will have an opening at the top, into which a pump turbine will be integrated in a pipe. When a valve is opened, water flows through the pipe into the sphere. The integrated pump runs in reverse and works as a turbine. The water drives the motor, generating electricity. Thus, the storage is discharged.

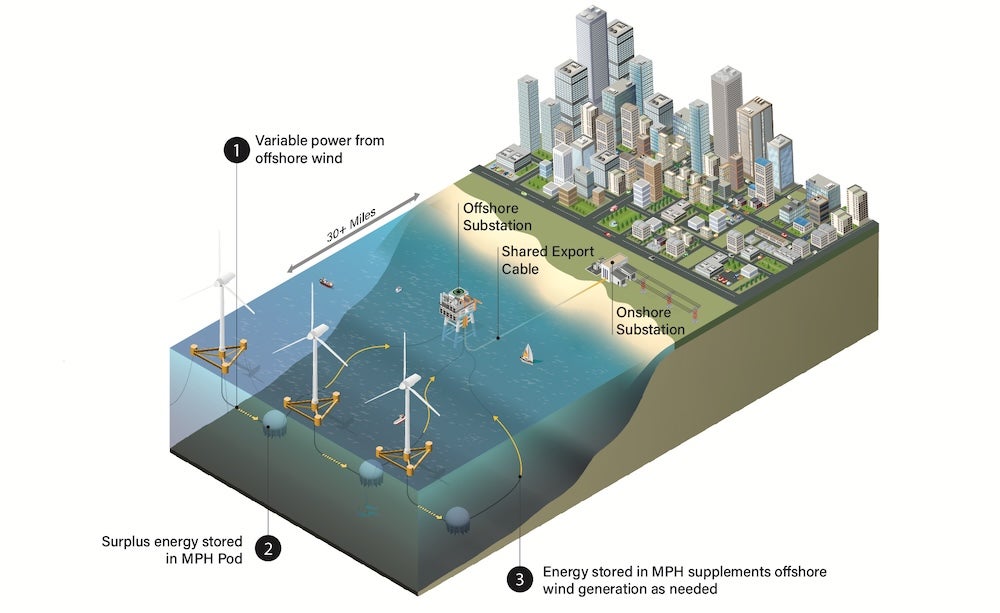

The idea dates back to 2011 and was developed by Prof. Dr. Horst Schmidt-Böcking and Dr. Gerhard Luther. An underwater cable connects to the power grid on land or to a floating transformer station of an offshore wind farm. To store energy, the motor pump pumps the water out of the sphere against the pressure of the surrounding water column. The cycle can then begin again. In a field trial with a 3m sphere in Lake Constance, Fraunhofer IEE researchers and their partners say they’ve already proven that this concept works well.

Ideal depth

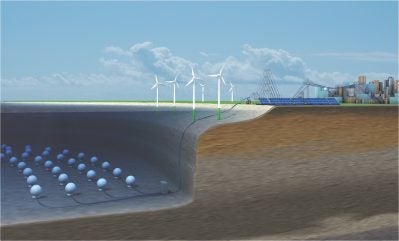

The capacity and performance of the spherical storage depend primarily on two factors: the volume of the spheres and the water column pressing on them. Fraunhofer IEE experts have calculated that water depths of 600 to 800m are ideal locations from an economic perspective. There, parameters such as pressure, the required sphere weight, and the necessary wall thickness are in optimal proportion to each other. Moreover, conventional underwater motor pumps can still be used at this depth. High-strength special concrete is also not necessary here.

There are more than enough potential locations for StEnSea spherical storage at this depth, as a GIS analysis of coastal marine areas shows. Fraunhofer IEE experts have taken parameters like bottom slope, currents, sediment displacement, or distance to land into account. For example, off the coasts of Norway, Portugal, the US East and West Coasts, Brazil, or Japan, the spherical storage could be installed in large numbers. The technology is also suitable for deep natural or artificial lakes, such as flooded open-pit mines.

Fraunhofer estimates the global storage potential of this technology is 817,000GWh in total. At the ten best European locations, it is still 166,000GWh. In comparison, the capacity of existing pumped storage power plants on land in Germany is just under 40GWh. Fraunhofer IEE researchers estimate storage costs at around 4.6 cents per kilowatt-hour, investment costs at 1354 euros per kilowatt of power, and 158 euros per kilowatt-hour of capacity. The lifespan of the concrete sphere is 50 to 60 years, with pump turbines and generators needing to be replaced every 20 years.

The efficiency over an entire storage cycle is slightly lower than that of a conventional pumped storage power plant, at 75 to 80%. This calculation is based on a storage park with six spheres, a total power capacity of 30MW and a capacity of 120MWh, with 520 storage cycles per year. StEnSea spherical storage is particularly suitable for two business models: for arbitrage, ie, buying electricity at low and selling at high market prices, and for providing ancillary services to stabilise power grids.

Scaling the technology

After the successful test in Lake Constance, the next step is to test the application in deep water under offshore conditions with the new project. The goal is to investigate and evaluate all steps along the manufacture, installation, operation, and maintenance regarding the intended size of the sphere.

“With the global energy transition, the demand for storage will increase enormously in the next few years,” says Bernhard Ernst of Fraunhofer IEE. “With the StEnSea spherical storage, we have developed a cost-effective technology that is particularly suitable for short to medium-term storage. With the test run off the US coast, we are making a big step towards scaling and commercialising this storage concept.”

As Sebastian Rose, Head of Engineering at Pleuger Industries, adds: “Our involvement in the StEnSea project underscores Pleuger’s commitment to innovation and sustainable energy solutions. With the significant support from both the US and German governments, we are transforming energy storage and contributing to a future where clean energy is more accessible and reliable for everyone.”