Dams and powerplants, even when being constructed and operated within stringent safety frameworks, can still pose significant risks, leading to accidents involving recreational water users such as boaters, kayakers, and swimmers. These individuals may inadvertently venture too close to these structures and get caught in the dangerous currents, often referred to as “drowning machines” due to the creation of powerful and inescapably subsurface currents.

To mitigate these risks, we propose a range of solutions, including regulatory measures, removal of obsolete dams, mandatory safety upgrades for new and existing installations, and the implementation of safety features such as warning signage and safety booms. Safety booms, in particular, play a critical role in preventing watercraft from approaching too closely and in providing means for individuals in the water to escape dangerous situations.

Since 2000, we have been engineering these safety booms, continually enhancing their design, performance and winter resilience to ensure year-round safety, even in harsh environmental conditions. The most recent iterations feature significant improvements in strength, unsinkability, and essential safety enhancements, including grab handles, casualty lifelines, warning signs, night-time visibility features, and integrated sensors, alarms, and cameras. These advanced booms are capable of stopping watercraft weighing up to an impressive 72 tons.

An innovative and highly secure gate system was also recently introduced, designed to facilitate controlled access through the safety booms. This system can be operated remotely from the shore or directly by personnel on a workboat, simply by pressing a button on a remote control.

This report delves into the different safety solutions, from regulatory measures to the practical application of safety booms and their customization options. Additionally, it focuses on recent safety boom implementations and their performance in different seasonal conditions, including winter.

Showcasing these advanced safety measures illustrates their significant role in reducing accidents and protecting human life in the vicinity of high-risk dam and powerplant areas.

Threats to human lives

Dams come in various sizes, ranging from massive concrete structures to small barriers as low as half a meter. Even low-head dams can generate strong subsurface currents known as submerged hydraulic jumps, which make them extremely hazardous. These “drowning machines” have been responsible for hundreds of fatalities in the United States in the last 20 years.

Almost 17,000 dams in the United States are classified as having high-hazard potential, meaning that their failure from any means, could result in loss of life, significant property damage, lifeline disruption, and environmental damage.

While data on accidents and fatalities at these structures in the United States is well-documented, a comprehensive overview for European rivers is lacking. There is no centralized system for reporting incidents, which hampers efforts to fully understand the scale of the problem.

In 2023, Dam Removal Europe (DRE) initiated the first attempt to gather data from across Europe, aiming to raise awareness of the safety risks posed by these structures to swimmers, kayakers, and other recreational users. Incidents involving “drowning machines” have been documented since the 19th century and continue to occur regularly. The key findings from this initial effort include:

- A total of 82 incidents resulting in 129 fatalities were recorded across 16 countries, with most incidents occurring since 2000.

- Several rivers had multiple incidents reported.

- Incidents involving “drowning machines” are highly likely to result in fatalities. In 80.5% of cases, at least one fatality occurred.

- The ages of those involved ranged from 2 to 59 years old, with most victims in their mid-20s to mid-30s.

- The individuals involved were participating in various activities, such as swimming, canoeing, rafting, fishing, or paddleboarding.

These findings underscore the urgent need for more effective safety measures beyond signage to protect recreational users.

Solutions

Removal of obsolete dams

The DRE report estimates 1.2 million dams across Europe, with over 150,000 obsolete. This means that they no longer fulfill their original purpose and often pose both environmental and safety risks.

The report also highlights ongoing efforts to address these concerns, noting that nearly 500 dams were removed in 2023 as part of river restoration projects. The removal of such structures is crucial for enhancing river health and safety, as obsolete dams are frequently associated with accidents involving swimmers, kayakers, and other recreational water users.

Regulatory action plays a key role in driving these efforts. For instance, the EU Nature Restoration Law, approved by the European Parliament on February 27, 2024, following an agreement by member states in November 2023, mandates the removal of man-made barriers to restore at least 25,000 km of free-flowing rivers in Europe by 2030. This law aims to improve both ecological connectivity and public safety.

Regulatory measures

The DRE report underscores the limitations of relying solely on warning signs for safety. In at least 15 documented incidents, signs were present but ignored, suggesting that such measures alone are not sufficient to prevent accidents. This points to two key issues: 1) warning signs, while necessary, are often ineffective on their own, and 2) there is a gap in the existing data and potentially in safety protocols across European rivers.

The report does not specify whether safety booms were in place at the time of these incidents, indicating a need for more comprehensive regulations. To effectively reduce the risk of accidents, regulations should not only mandate the installation of warning signs but also require physical safety interventions, such as safety booms, coupled with public education initiatives and stricter enforcement.

Safety booms

Safety booms provide a physical barrier to prevent swimmers, kayakers, and other recreational users from entering dangerous areas. These booms can be customized to suit the specific conditions of a river or waterway, significantly reducing the risk of fatal accidents. By offering an essential layer of protection where traditional warning measures may fall short, safety booms play a crucial role in protecting human lives near dams and other hazardous water structures.

Safety projects

Kinloch Rannoch Project 2023

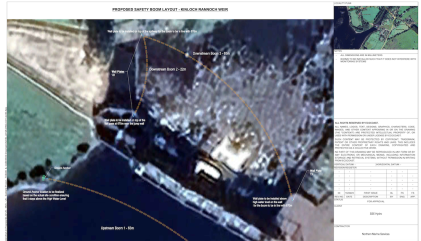

Kinloch Rannoch Weir is a historic structure situated on the River Tummel in the Scottish Highlands, regulating the flow of water from Loch Rannoch into the Dunalastair Reservoir. This adjustable low dam is designed to maintain sufficient upstream water depth while allowing controlled water flow.

To enhance safety for water users, particularly kayakers, the installation of barriers is necessary to prevent access to hazardous areas near the infrastructure. These barriers, supported by clear signage, aim to ensure that no one approaches the structure, reducing the risk of accidents and improving overall safety. Bolina Watercraft Safety Booms (CAB400) are specified for this purpose, providing effective protection in the area.

Figure 1 shows the layout plan for booms and supporting components. The upstream boom, which is 63 meters in length, is anchored by a ground anchor at one end. Moving downstream, there are two additional booms: the first is 65 meters in length, following a curved path toward the shore, and the second is 22 meters long, positioned parallel but closer to the shore-based structure.

Wall plates are installed at specific locations to support these downstream booms. One wall plate is placed above the high-water level on the wall to ensure the boom is in line with the 670-meter mark. Another wall plate is positioned near a fish pass, also at the 670-meter mark near a jump wall. A last wall plate is installed on top of the spillway for the boom to be in line with the 670-meter mark.

Two ground anchors are indicated in the plan, both for the upstream boom. The locations of these ground anchors were to be finalized based on the actual site conditions, ensuring that they remain above the high-water level.

Clunie Dam Project 2024

The Clunie Dam, located at the eastern end of Loch Tummel in Perth & Kinross, Scotland, is a critical part of the Tummel Hydro-Electric Power Scheme. By raising the loch’s water level by 5 meters, it provides the necessary water head for the Clunie Power Station, which lies 3 kilometers to the east and is supplied through an underground aqueduct.

Given the proximity of the Loch Tummel Sailing Club upstream from the dam, safety is paramount. The club is heavily used for various water-based activities, including sailing lessons, kayaking, paddleboarding, and events in collaboration with the Scottish Coastal Rowing Association. Its fleet includes dinghies, catamarans, and small keelboats.

To ensure the safety of club members and the broader community, Bolina Watercraft Safety Booms will be installed within the coming weeks. As the club continues to grow, the installation of the safety booms is critical in protecting both enthusiasts and casual users of the Loch, reinforcing the importance of proactive safety measures in such a dynamic recreational environment.

Winter performance

As winter approaches, it is crucial to evaluate the performance of Bolina Watercraft Safety Booms in challenging conditions. These booms are specifically engineered to withstand severe winter conditions, including harsh storms and freezing temperatures, without compromising their protective function. The booms are known for their durability and reliability, particularly in cold-weather environments. Their superior performance in arctic winters and storm-prone regions is attributed to the innovative materials and thoughtful engineering behind their design.

Safety boom features & benefits

Enhanced float molding process

Key to the booms’ durability is the enhanced float molding process. Unlike standard floats, which typically measure 4 millimeters in thickness, Bolina Watercraft Safety Booms use a high quantity of powder during molding to create 6-millimeter-thick floats. This added thickness makes the floats more resilient to freezing temperatures and better equipped to endure the challenges posed by winter climates.

Foam-filled floats for increased reliability

In addition to their thickness, the booms feature foam-filled floats, unlike air-filled counterparts commonly used by competitors. This foam-filled design ensures that the booms remain virtually unsinkable, even in extreme conditions where freezing temperatures might cause air-filled floats to crack or allow water to penetrate and freeze inside.

By preventing water ingress, the floats maintain their integrity, protecting the boom’s functionality even in the most frigid environments.

High-quality galvanized shackles for secure installation

The booms are also secured with high-quality galvanized shackles, providing additional weather resistance and ensuring the entire system remains operational despite exposure to ice and heavy winds. This meticulous attention to material quality and weatherproofing guarantees that the booms can withstand prolonged exposure to winter elements.

Proven performance in extreme climates

Over the past two decades, Bolina Watercraft Safety Booms have consistently proven their durability in cold-weather climates across Northern Europe, the UK, the US, and Canada. Their performance in regions like the Netherlands’ De Biesbosch National Park – one of the largest freshwater tidal wetlands in Northwestern Europe – further attests to their resilience. Deployed in this ecologically sensitive area, the booms were chosen specifically for their proven reliability in harsh winter conditions.

Similarly, they are utilized at Lac L’Heureux Dam in Québec, Canada, where they face challenging winter weather (figure 4). This installation is another testament to the effectiveness of Bolina Watercraft Safety Booms in safeguarding critical water environments, even in the most extreme climates.

New safety booms for enhanced security

In response to the growing threat of deliberate attacks on dams, powerplants and other hydraulic structures, whether from water-borne or other means, a new line of safety booms were designed to offer superior protection against fast-surface boats and underwater threats. This new boom is purpose-built to excel in the most challenging environments, offering an extreme break load of 72 tons and unmatched durability.

Key features

- Secure Gate System: The booms come with an advanced gate system that allows controlled access for authorized watercraft while ensuring that unauthorized craft are effectively blocked. This system is engineered for robust security in high-risk areas.

- Integrated Warning Signs: Warning signs can be attached directly to mooring floats, eliminating the need for additional buoys. This integrated design improves both safety and aesthetic simplicity while maintaining high visibility.

- Grab Handles and Casualty Lifelines: These safety features are incorporated into the boom design, providing essential life-saving equipment in case of emergencies. The grab handles and lifelines make rescue operations faster and more efficient.

- Night-Time Visibility Enhancements: Reflective strips or lights can be added to the booms to ensure they are visible in low-light conditions, providing additional safety for both users and operators during night-time operations.

- Integrated Safety Features: Beyond signage, advanced technologies such as sensors, alarms, and cameras can be integrated into the system to offer real-time monitoring and alerts. These features help detect approaching watercraft or individuals entering restricted areas, triggering alarms to warn them and notify authorities.

By combining traditional safety measures with modern technology, these integrated solutions offer a multi-layered approach to protecting human lives near hazardous water structures, ensuring that potential risks are addressed promptly and effectively.

Enhanced security options

To further increase the boom’s defensive capabilities, the floats can be equipped with oversized spikes that add to the barrier height. These spikes are designed to puncture inflatable, fiberglass, and aluminum hulls, effectively stopping unauthorized watercraft in their tracks.

In addition, the boom can be outfitted with a fence on top of the floats and a net underneath to provide an additional layer of stopping power.

Conclusion

Advancements in safety booms have significantly strengthened the protection of high-risk areas surrounding dams and powerplants, effectively addressing both natural hazards and evolving security threats. These innovations mitigate the dangers posed by “drowning machines” and ensure robust performance even in winter conditions, demonstrating a comprehensive approach to enhancing safety in challenging environments.

However, enhancing safety in these critical areas requires a multifaceted strategy that goes beyond the use of safety booms. Regulatory measures play a crucial role in establishing safety standards and ensuring compliance, while the removal of obsolete dams is vital for reducing risks associated with aging infrastructure. By addressing these issues, we can further protect recreational water users and the communities surrounding these vital structures.

The latest safety booms not only offer increased resilience and customization options – such as integrated warning systems, lifelines, and advanced security features – but also contribute to a broader safety framework. Their successful deployment in various global locations has proven their durability and effectiveness, making them indispensable in safety protocols.

With the introduction of a new line of safety booms designed for high-threat scenarios, operators can ensure a higher level of security against unauthorized access or deliberate attacks. As we continue to push the boundaries of design, functionality, and resilience, these safety booms, alongside regulatory measures and the removal of obsolete infrastructure, represent a critical component in protecting both human life and vital infrastructure. Their ongoing refinement will undoubtedly play a key role in enhancing dam and power plant safety worldwide, adapting to the challenges of tomorrow while safeguarding our communities today.

References

FEMA. (2024). National Dam Safety Program: Resources for States. Retrieved from https://www.fema.gov/emergency-managers/risk-management/dam-safety/resources-states

Mouchlianitis, F.A. (2024). Dam Removal Progress 2023. World Fish Migration Foundation.

School of GeoSciences, University of Edinburgh, and The Royal Scottish Geographical Society. (2022). Report on Dam Safety and Hydroelectric Development in Scotland.

CANMORE, National Record of the Historic Environment Scotland. (2024). Dam Infrastructure Overview. Retrieved from https://canmore.org.uk

SSE Renewables. (n.d.). Retrieved from https://www.sserenewables.com

Dam Removal Europe. Retrieved from https://damremoval.eu

World Energy Media, Promoter of World Energy Cooperation. (2024). Record-Breaking Surge as Nearly 500 Dams Removed Across Europe in 2023, Report Reveals. Retrieved from https://www.world-energy.org/article/41614.html

Author information

Filip Stefanovic, BSc. in Civil Engineering, joined Ecocoast in the United Arab Emirates in 2017 as a Technical Engineer, specializing in marine contracting and coastal protection services. Currently, he serves as Regional General Manager, overseeing engineering, operations, and logistics, while continuing to be based in the UAE.

Michael Sims is currently serving as Key Account Manager at Ecocoast Ltd, formerly known as Bolina Ltd, based in the United Kingdom. Joining the team in November 2021, Michael brings a wealth of experience and expertise to his role. His primary focus lies in strategic development and management of key accounts across the United Kingdom, North America, English-speaking Africa including partner networks in Europe. Michael’s responsibilities encompass identifying and capitalizing on opportunities for the deployment of marine safety, security and environmental booms in diverse settings such as inland waterways, ports, dams, and other critical infrastructure projects.

Acknowledgement

This paper was originally presented at Hydro 2024