What were the initial motivations behind Carpi Tech’s entry into the hydropower industry, and how have these motivations influenced the company’s growth?

Carpi was established in 1963 as a contractor specializing in waterproofing special roofings and small basins with synthetic geomembranes. Creativity and foresight, which were in the DNA of the company since the beginning, and the proximity to a mountainous area (the western Alps of Italy) rich in large water management structures needing rehabilitation, led the company to develop and patent special geomembrane systems and anchorage devices that could be used in larger projects. Gradually, Carpi’s focus shifted towards the rehabilitation of large hydropower dams and canals, where its new techniques could provide significant benefits not only to the hydropower and water management industry, but also to the company itself. This growth trajectory led Carpi to expand into other Alpine nations, buoyed by the success of its pioneering projects.

Can you elaborate on a particularly challenging project from Carpi Tech’s past

and how the company overcame obstacles to achieve success?

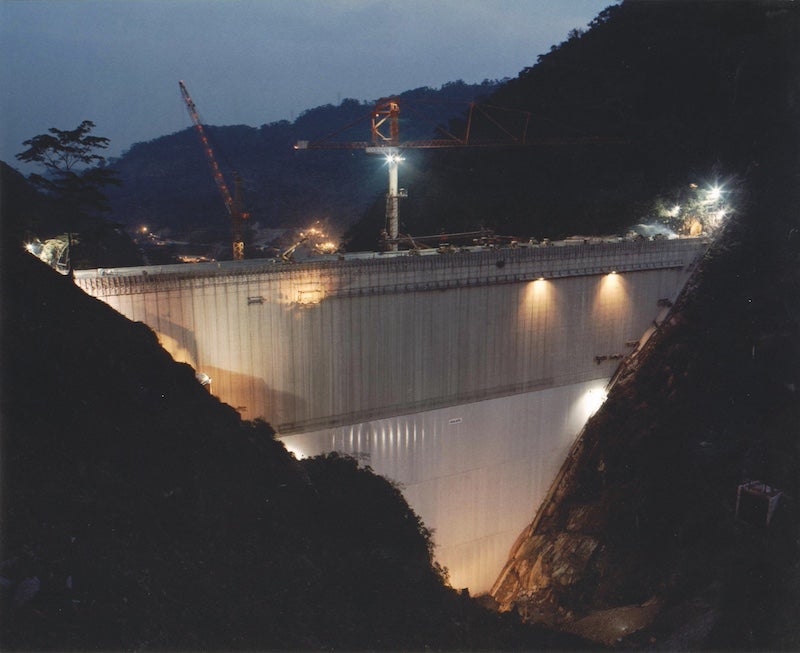

Miel I dam in Colombia, 188m high and at that time the highest RCC dam in the world, was a very challenging project. The dam was designed with an upstream slip-formed reinforced concrete facing. To meet contractual schedule, this facing was modified to a Carpi exposed geomembrane system placed on a 0.4m thick layer of grout enriched RCC. To further expedite construction of the water barrier, it was decided to install the geomembrane system concurrent with construction of the dam. The height of the dam required dividing installation in six separate horizontal sections, in function of the horizontal drainage compartmentation, with the geomembrane installed in a lower section while the RCC works were ongoing in the section above. A special railing system had to be designed to support and protect the travelling platforms from which workers carried out installation of the geomembrane system.

To accurately monitor the performance of the geomembrane, a face drainage system was provided, divided in separate horizontal and vertical sections, for a total of 45 separately drained compartments. Waterproofing works started on October 8, 2001, and were completed on September 7, 2002, covering a total 31,453m2 of exposed geomembrane. Staged installation allowed for completing the waterproofing system and starting reservoir impounding while civil works were still ongoing at crest. We are proud to say that the average leakage registered from the entire geomembrane’s drainage system has so far been of 2 l/sec.

How has Carpi Tech’s collaboration with other industry stakeholders evolved over time, and what impact has this had on project outcomes?

From the outset, Carpi has consistently tried to work in close collaboration with the owners and the consultants involved in each project. This is done for the sake of the project, to ensure that the best solution is selected and implemented. Over the years, this cooperation has increased the confidence of owners and designers in our systems and in our reliability. Mutual respect has fostered stricter cooperation, sometimes providing improvements in design of the geomembrane system, and in some cases also optimising the design of the dam itself.

Carpi has also always worked in close contact with its suppliers, fostering the development of high-performance products tailored to its specifications, such as geomembrane having outstanding durability for exposure to demanding environments, synthetic drainage materials, different types of anchorage profiles etc. Our unique products have allowed us to develop innovative solutions, some of which are patented. Carpi’s growth has certainly also benefited from these relationships.

Could you share a significant technological breakthrough or innovation that has been pivotal in shaping Carpi Tech’s reputation in the hydropower sector?

Our history has been punctuated by several breakthroughs. The development of geomembrane systems that could be installed underwater was the first important one. Carpi initiated its exploration of underwater geomembrane technologies in the early 1990s. This in-house research culminated in a two-year research project conducted from 1995 to 1996, in collaboration with the US Army Corps of Engineers at their Waterways Experiment Station. The Corps validated the Carpi solutions, which were first applied in 1997 to waterproof the upstream face of Lost Creek arch dam in the US, and have since been installed in several dam projects around the world. This helped shape our reputation as leaders in geomembrane systems design and installation in the dry and underwater. So far more that 20 projects have been completed underwater.

A second breakthrough was our patented flexible geomembrane anchorage system embedded in extruded porous concrete curbs, which allows for constructing new embankment dams in a safe, faster and less expensive way. This solution and its further developments have given birth to what is now known worldwide as Geomembrane Faced Rockfill Dam.

Finally, Carpi invented an innovative system utilizing its flexible geomembranes and watertight heavy-duty zips, used for lining canals underwater, even in flowing water conditions.

What role has sustainability played in Carpi Tech’s historical projects, and how has the company adapted to changing environmental standards and expectations?

Since day one, sustainability has been a cornerstone of our projects’ design and implementation. Our systems are purposefully crafted to be more environmentally friendly than traditional alternatives. In recent years, our dedication to environmental stewardship has intensified significantly. Carpi has established ambitious targets aimed at substantially reducing our environmental footprint. Through ongoing performance monitoring, awareness initiatives, collaboration with suppliers, and targeted action plans, our commitment to sustainability continues to grow stronger over time.

How has Carpi Tech’s workforce evolved over the years, and what key skills or expertise have been instrumental in driving the company’s success in hydropower projects?

In the pioneer period, Carpi had in total about 10 employees based in Italy. At present, we are a group with headquarters in Switzerland and worldwide operation, with four poles (Europe, India, North America and Latam) and offices in 10 countries. Our workforce amounts to about 120 employees, to which local labour trained and approved by Carpi is added for specific projects. Our success has two main driving forces – quality and safety. Quality in respect to design, materials, and installation procedures and controls. Safety for our employees and for all people involved in a project. Our clients trust in this reliability, often resulting in us being entrusted with multiple projects by the same owner.

What recent projects has Carpi Tech been involved in, and how do these projects reflect the company’s current priorities and values?

In the past few years, we have been increasingly involved in lining of upper and lower reservoirs of new pumped storage schemes, and in developing underwater geomembrane systems to repair deteriorated canals without impacting on operation. We have been approached by clients with demanding projects because we strongly believe that saving water, developing sustainable energy sources, and preserving the environment, is a common responsibility. It’s imperative that we encourage the proliferation of projects aligned with these principles and strive to ensure they are safe, efficient, durable, and profitable.

How does Carpi Tech approach risk management in its present-day hydropower ventures, particularly in light of changing regulatory landscapes?

Risk management begins at the inception of each project, initiated by a preliminary analysis which always takes into consideration the regulatory framework. The more we enter in the project’s details, more elements are added to the assessment and, if required, preventive and corrective actions are implemented.

How does Carpi Tech ensure the quality and sustainability of its waterproofing geomembrane systems for hydraulic structures?

Quality and sustainability of our system depend on the design, materials and installation process.

Carpi’s extensive experience and references attest to the quality of our designs. Sustainability is a key focus, as we strive to optimize solutions for each project, minimizing their environmental impact.

Regarding the materials, quality and sustainability are ensured by a constant open dialogue with suppliers with whom Carpii has established longstanding relationships. Together we inspect the materials, evaluate their performances, and develop new materials or systems.

During the installation process, a specific Quality Control Plan tailored for each project is followed at each construction phase. All workers undergo training on applicable procedures and associated risks.

Can you discuss any recent partnerships or collaborations that have enhanced Carpi Tech’s capabilities and competitiveness in the hydropower market?

Carpi has recently co-operated with a highly reputed engineering firm to study and develop underwater techniques allowing global rehabilitation of hydropower and navigation canals, by restoring the waterproofing and / or mechanical protection functions. The aim was to treat significant areas with solutions having minimum impact on the operation of the hydroelectric plant or on navigation, and with sustainable economic conditions. One of these projects was awarded the 2022 Innovation Award by the International Commission on Large Dams (ICOLD). Some aspects have been highlighted that are subject of further development or improvement.

In what ways does Carpi Tech prioritize safety and quality assurance in its current projects, and how are these aspects integrated into project planning and execution?

‘Safety first’ is our motto. Based on the installation method and on the project features, safety risk analysis is documented during project planning. It is a live document which can be modified anytime whenever necessary. A quality assurance plan is also part of the project documentation.

One of our main values is our people. By carefully selecting the right team, providing thorough training, and involving them from the planning phase onward, we ensure the safe and high-quality execution of our projects.

How does Carpi Tech stay abreast of emerging trends and technologies in the hydropower industry to maintain its position as a leader in innovation?

By keeping in our DNA the foresight and creativity that brought us where we are. We try to anticipate trends, and to be always one step ahead of our potential competitors by designing new technologies via our internal R&D Department and our Underwater Department. Our engineers, geologists and underwater experts develop systems, equipment, methods, and new patents, to keep our leading position.

We cooperate with several Institutes of Technology (e.g., TUM, the Technical University of Munich, Ecole Polytechnique de Losanne, Politecnico di Milano) and other research institutes in Europe and the US. We strive to be immediately active in emerging market sectors such as floating solar panels and floating covers.

What innovations or advancements is Carpi Tech planning to introduce in the hydropower industry in the coming years?

We intend to continue study and research in the field of pumped storage schemes and of underwater installation in flowing water. The objective is to further simplify/improve design, and also with the aid of new equipment and machines, to devise methods to make installation even quicker and more efficient than at present, to allow maximum safety and earlier commissioning.

Hydropower is in itself a sustainable technology. Carpi can contribute to make it grow further and be even more sustainable by providing waterproofing methods that help maintain hydropower plants in safe operation without disruption, and by preserving water. In new construction we offer solutions that allow storing higher volumes of water, are constructed more quickly, are durable, environmentally friendly with a carbon footprint four times less than that of concrete linings, and require no maintenance.

Does Carpi Tech plan to leverage digitalization and data analytics to optimize performance and efficiency in upcoming hydropower ventures?

Carpi considers digitalization and data analytics as a key part of our business now and in the future. We look for optimisation in every department from sales and business development all the way through to site installation and project hand over.

For example, we use some of the most modern software to trace and track projects from initial conception through to award. During execution our installation teams use the most modern welding equipment with WiFi & GPS compatibility that can record and log all the welding parameters and ensure compliance with quality protocols in every corner of the world.

In what ways is Carpi Tech preparing its workforce for the demands of tomorrow’s hydropower industry through training, upskilling, and talent development programs?

Our worldwide presence continuously requires training and upskilling of our workforce in the countries where we have large projects in sight. Discovering and developing talents is favoured by the relatively small size of each of our companies, and by the wide range of expertise available in our headquarters and poles where, in addition to internal webinars, knowledge is passed from older to younger colleagues, and different tools and information are made available, in a continuous process of professional upskilling. All Carpi employees attend a minimum of one training course a year on specific subjects.