When it comes to excessive wear on mechanical equipment, cavitation and erosion are major issues. Cavitation is a kind of surface fatigue caused by changes in pressure as water flows through equipment. In places where the pressure drops, such as behind impeller blades, bubbles of water vapor can sometimes form spontaneously. When these bubbles collapse, the resulting shock waves results leads to pitting, cracking and eventual disintegration of the impeller.

Erosion can also cause excessive wear over time due to sand particles in the water colliding with a component.

Cavitation and erosion can happen to hydraulic machines of all types, sizes and ages and it’s not possible to completely eliminate them. Instead, regular repair is needed to rebuild components to their original dimensions with a material that provides high surface hardness and toughness. This will return the hydropower plant to service at its original level of efficiency, while extending its service life.

A challenge is that cavitation and erosion are different wear mechanisms and can happen separately or in combination with each other and with corrosion. The resulting wear is experienced differently at every site, depending on the factors such as the pressure and load, as well as the type and size of sand and water flow.

To overcome this, a broad range of coatings is available for repair of equipment such as Francis, Kaplan, propeller and bulb turbines, as well as draft tubes, impellers, pumps and valves, and wicket gates. Wear-resistant alloys can be applied with techniques such as HVOF (high velocity oxygen fuel), arc spraying and welding. Cold polymeric coatings can also play a role.

The key to a successful repair is careful choice of repair materials and application techniques, depending on the type and extent of wear experienced locally.

Cavitation-resistant alloy

One important repair alloy was developed by Hydro-Quebec, a leading Canadian hydropower generation company. It was experiencing cavitation and erosion on its 300 generating units ranging from 1MW to 350MW in capacity. This prompted it to develop a special stainless-steel alloy to resist damage from severe cavitation erosion on hydraulic turbine runners. We have been producing this alloy under the trade name CaviTec since 1994 to extend the life of hydropower equipment around the world. Under testing, the alloy has proven to last six times longer than other stainless-steel grades such as 308 or 309. It is an austenitic alloy containing chromium, cobalt, silicon and manganese. These act together to lend strain-hardening and shock damping properties, which are ideal to resist cavitation and erosion.

Strain-hardening means that during cavitation, the pressure waves hitting the material’s surface cause a reaction in the microstructure that increases surface hardness. This provides added durability so that the component can remain in service over much longer time periods than with other materials.

Recent developments have extended the alloy’s application to improve the quality of the wear coating and its surface finish. For example, we introduced pulse welding with minimal spatter and have optimized application parameters to minimize porosity.

Welding cavitation repairs

Cavitation often results in the loss of material from the surface so material loss can become quite significant over time. This creates a need to rebuild components with welding repairs. This involves removing damaged material with arc-air or plasma gouging before grinding the gouged surface to remove oxides and slag. The final step is grinding to shape before the component can be returned to service.

In cases where a part needs to be significantly rebuilt, it’s important to lay down a base layer in a stainless steel such as grade 309L stainless steel as the overlying CaviTec layer should be no thicker than 9.5mm.

A set of three 60MW Francis pump turbines in Austria has benefited from CaviTec coating. The pumps can deliver a flow of 375 to 500 litres per minute against a head of 50 to 200 metres. The challenge is that severe cavitation occurs on the pump turbine’s inlet edges at the upper limit of this range.

Changing the hydraulic shape of the component did not solve this problem, so the operations team carried out a trial of a 5 mm thick layer of cavitation-resistant alloy. Testing found that this increased the repair interval from 3000 to 9000 hours, tripling the service life.

Thermal spraying to resist erosion

Where erosion resistance is important, it is possible to use thermal spraying techniques. These enable coatings that are both thin and dense. Low thickness is important for a machine’s efficiency, while density helps to withstand the impact of hard sand particles over time.

However, it’s also important to consider the long-term performance and repairability. An important measure of this is bond strength. With this in mind, our technicians typically prefer HVOF and arc spray. Both have a high bond strength for new and repaired coatings, and this ensures a good service life. The choice of technique depends on the type of coating.

HVOF applies coatings of powdered materials such as tungsten carbide cobalt chromium (WC/Co/Cr) at high velocity. This provides very high protection against erosion and also resists cavitation. Because the technique uses high velocity, rather than high temperature, it avoids thermal effects affecting the underlying component.

This type of coating can be applied either in small spots or as coatings across an entire component. The technology is mobile, making it possible to carry out repairs in situ.

Another option for erosion resistance is so-called amorphous materials. These materials typically contain chromium, boron and silicon and bond well with the underlying steel and create a dense coating. They are only available in the form of cored wires, so need to be applied using arc spray, which uses an electric arc to deposit material with faster deposition rates than HVOF. This makes them more economical than HVOF but do not match the extremely high surface hardness of tungsten carbide.

One hydropower plant in Austria was experiencing excessive erosion on a 6MW high pressure pump turbine due to heavy content of sand in its driving water. Sand particles of 0.5mm and larger were leading to erosion between the shaft seals and the runners.

Depending on the water quality, this resulted in a service life that varied from 3000 to 6000 hours – and in some cases, the operator found that the wear reservoir was destroyed within a few days. As a result, the turbine was experiencing excessive leakage, requiring immediate repair.

As a preventive measure, a repair technician used the HVOF technique to apply a 0.3mm coating. Inspection after 2200 hours of operation found that wear was no higher than 0.025mm. This indicates that with HVOF, the repair intervals can be considerably longer at the site.

Laser cladding for toughness

Laser cladding is another technology for rebuilding and redimensioning components. It is possible to use it on very large components, up to 15m in length, with automated welding for consistent high quality.

During laser cladding, metallic powder or wire on the surface of the workpiece is heated with a laser to form a melt pool that creates a strong metallurgical bond with the surface. This strong bond creates a tough coating for withstanding erosion and cavitation.

It has the additional benefit of short heating times due to the precision of the laser, which limits heat exposure. Furthermore, it offers flexibility over choice and grading of the coating as powders or wires can be mixed during application.

One example of a laser-clad repair in the hydropower industry was a six-ton component in Norway. It had experienced heavy wear and required significant rebuilding. The operator wanted to avoid risking thermal distortion or damage to the part, along with potential environmental harm from emissions produced by burning welding gases. Therefore, our subsidiary Castolin Trio Norway used a 6kW laser cladding machine to build up the part with almost 250 kg of carbon steel.

The approach enabled the return of the high-value part into service quickly while minimizing environmental impact by using zero-emission Nordic electricity to power the laser and eliminating emissions that would be required for a traditional welding repair by burning welding gases.

Ceramic surfacing polymer for cast iron repair

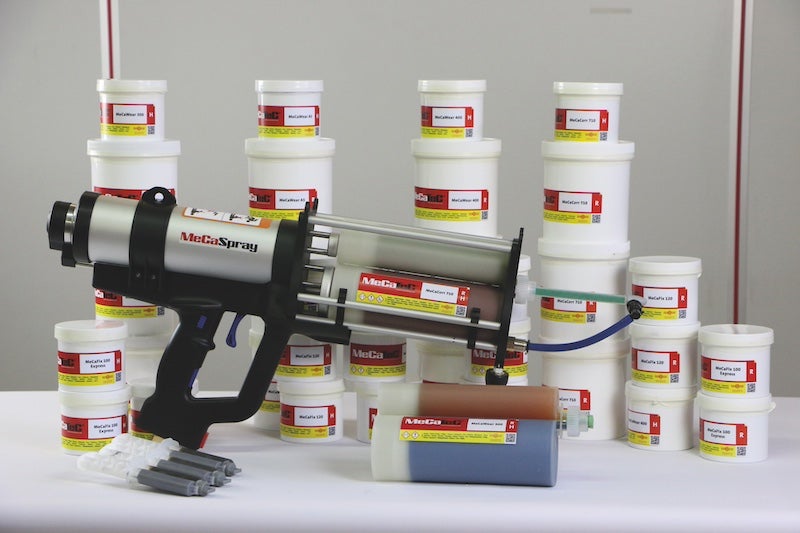

Ceramic surface polymers are another type of material that can provide resistance to cavitation and erosion. These are composite materials that combine the strength and heat resistance of ceramics with the flexibility and ease of processing of polymers. Available under the MeCaTec name, they are supplied as a compound in two parts that are combined on site and then applied with a trowel, brush or as a spray.

They can be used for curative maintenance to repair and rebuild cast iron components, pipework, valve and pump bodies. Ceramic polymers are also helpful for preventive maintenance to keep components in service for longer.

One example at a hydropower plant was on a water supply pipe on a cast iron storage tank. It had become perforated over time. Ceramic polymer was the ideal repair material as welding or thermal repair of cast iron is complex and challenging.

The repair compound was used to repair and fill the perforations to return the component to service quickly.

When carrying out repairs of hydropower components, it’s essential to evaluate the application to choose the most appropriate materials and techniques.