Digital twin technology – a virtual replica of a physical system, process, or product that enables real-time monitoring, analysis, and optimisation of its performance – has gained significant attention in recent years as a promising approach for improving the efficiency, reliability, and sustainability of various industries, DongSoon Park and Hojun You state in their recent research published in the journal Water.

As the authors claim, active discussions are also underway about whether efficiency and productivity can be increased by digitalising traditional knowledge-based watershed and water infrastructure management.

The water management sector is currently experiencing a significant wave of digital innovations – such as investigations into changes in surface water area using the Google Earth Engine cloud platform, or examining the characteristics and design of a Web GIS Platform for monitoring water resources, and exploring the potential of digital solutions to enhance public awareness of urban water management issues.

However, despite these ‘commendable efforts’, Park and You say that to the best of their knowledge, there have been few attempts to apply digital twin technology across an entire dam and river basin for comprehensive digitalised smart water resource management and data-driven decision-making. Therefore their paper, called A Digital Twin Dam and Watershed Management Platform, provides an overview of realistic digital twins in the field of water resource management, their applications, as well as potential future developments.

“The advantage of digital twins in large-scale water management lies in innovations in productivity and efficiency in the way we work,” the authors explain. “They can also reduce time and labour, and improve reliability in the decision-making process. In the field of water management of dams and rivers, the benefit of digitalisation is ‘data-based smart water management.’ The goal is to solve many tasks that have been routinely carried out in the past more intuitively, reliably, and quickly with the help of the digital world.”

Advantages of digital twins

The advantages of the pursuit of digital twins in smart water resource management can be summarised by five categories.

- Visualisation: Visualise the three-dimensional representation of geospatial information and data analysis results for easy understanding.

- Intuition: Intuitively acquire information or knowledge with the help of digitisation without a complex reasoning process.

- Data synchronisation: Increase productivity by providing real-time synchronisation of related data.

- Extract value and knowledge from information: Provide information with engineering value to users and contribute to rapid and reliable decision-making.

- Sustainable use and practice: A usability-based platform that practitioners can continuously and conveniently use in their actual work.

Digital twin for Sumjin River Basin

Park and You introduced a digital twin water management platform, ‘K-Twin SJ’, for the entire 173km long Sumjin River basin in South Korea. It was designed in May 2021 and finished in December 2022. User services began in April 2023 for internal customers at Korea Water Resources Corporation in the Republic of Korea.

The project includes high-precision 3D geospatial information on the whole watershed, real-time water management data visualisation, flood analysis simulation, AI dam operation optimisation, AI slope geometry generation, levee safety evaluation, AI CCTV image analysis, simpler flooding potential prediction, and an advanced drone monitoring system.

To create 3D geospatial information, high-resolution helicopter LiDAR mapping was conducted for the river. Reality modelling by drone photogrammetry and 3D data reduction was performed for three dams, 85 river bridges, and three weirs.

Data from dam operation, weather forecasts, river water level stations, and CCTV were combined and visualised on the platform.

An AI-driven intelligent CCTV image analysis was added to the platform for early warning, and an automatic drone monitoring system was developed to supervise the dam reservoir and downstream river, even amid rainfall and windy conditions. In addition, seepage analysis and slope stability analysis for levees were integrated into the platform.

Three types of dam and river simulations were implemented on the platform – a rainfall-runoff model, a hydraulic river flow prediction model, and a river flooding model. In addition, AI-driven smart flood prediction and an optimised dam discharge model were loaded to minimise flood damage to the downstream river and to secure dam safety. Through the platform, data-based smart water management is implemented. By linking dams and rivers into one system, the digital twin platform will contribute to a multidisciplinary model that integrates various components to enhance the productivity of water management against flooding.

The authors conclude that although this is a powerful digital platform for water resource operation and management, it has only recently been launched, and further research is required for future verification and validation. Quantitative and qualitative evaluations of the digital twin dam and watershed management need to be studied, focusing on enhancing productivity and efficiency in the decision-making process.

Digital twins tailored for tailings dams

A digital twins research project which has been described as being a paradigm shift in monitoring tailings dams, was recently awarded a prestigious prize at COP28. Digital Twins 4 Tailings Dams is a satellite-based early warning system to monitor the stability of tailings storage facilities, preventing potential catastrophic failures. It won the Data Sciences & AI-Enabled Solutions prize at the COP28 Prototypes for Humanity initiative, which finds innovative solutions for social and environmental issues. The winners were selected from more than 3000 entries submitted from 710 universities in 108 countries.

The winning research group comprises PhD student Maral Bayaraa and Dr Cristian Rossi from the University of Oxford, and Dr Brian Sheil from the Laing O’Rourke Centre for Construction Engineering and Technology at the University of Cambridge in the UK.

Bayaraa is from Mongolia which is one of the most resource-rich countries in the world. “I’ve seen the huge amount of good mining can do,” she said. “But I’ve also seen the really dark side of mining and that’s why I’ve always wanted to be a part of this conversation – making mining more sustainable. I believe the award is a part of the recognition of the huge role that Earth Observation plays in tackling some of today’s biggest challenges…Our research focuses on global monitoring of critical infrastructure, such as tailings dams that contain toxic mine waste.”

The World Bank highlights a need for three billion tons of metals for the clean energy transition, which is intensifying challenges for the mining sector as over 98% of materials like copper end up as waste, stored in tailings facilities. With over 30,000 globally, a quarter of these are abandoned and unmonitored. By integrating geotechnical engineering, satellite remote sensing, and machine learning, the Digital Twins 4 Tailings Dams project aspires to establish a digital twin system to monitor these critical infrastructures.

“We are delighted to have our research on tailings dams recognised in this way,” Dr Brian Sheil said. “This award spotlights the transformative role of satellite monitoring, machine learning, geotechnical modelling and digital twin technology will have in how we manage tailings dams worldwide. This research has been intrinsic to the wider Digital Twins research that we are carrying out in the Laing O’Rourke Centre for Construction Engineering Technology at University of Cambridge, where we are working towards achieving step-change improvements in sustainability, productivity and safety for the construction industry.”

Digital twins in Spain

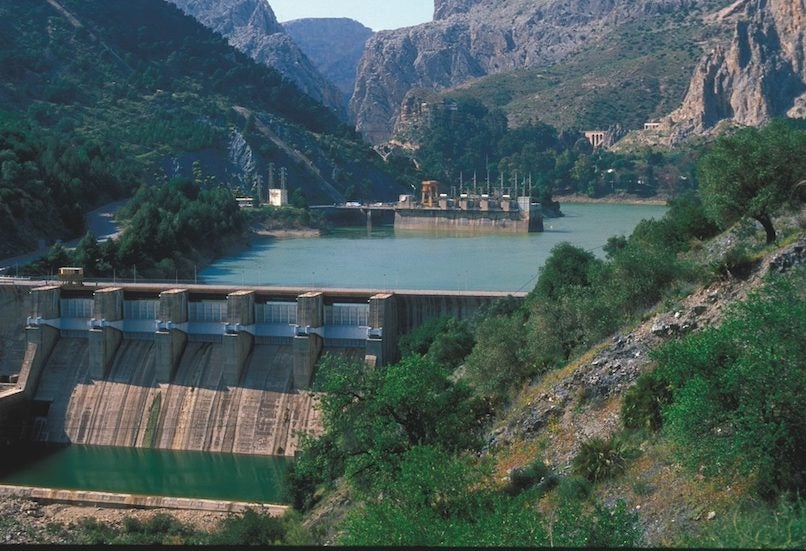

Spanish electricity company Endesa has created digital twins of its hydroelectric power plants, which not only provide improved monitoring but also allow for 3D virtual tours of the facilities.

“Endesa has 153 hydroelectric power plants distributed throughout Spain, their management is essential, but their location sometimes causes problems. So creating these digital twins has been crucial to improve our understanding and their operation,” said Santiago Dominguez, Endesa’s Head of Hydroelectric Generation. “When people think of hydroelectric power plants, they don’t have an idea of their size, how they work and how important they are in giving us 100% renewable supply.

The first digital twin pilot for virtual tours was launched in 2023 at the El Pintado hydroelectric power plant near Seville. It was developed by Endesa’s Hydro Iberia Predictive Maintenance team, which developed a model similar to Street View but inside a power plant. To do this, 360-degree cameras and Lidar scanners with the latest technology were installed. And with them, it was possible to obtain the necessary depth to generate 3D spaces with high-resolution image quality.

This application allows a virtual visit to the facility where all the installed equipment and infrastructure of the plant can be viewed. This model is useful in providing virtual visits for suppliers or internal personnel, visualisation of equipment and instrumentation, taking measurements on the installation, visualisation of the plan of a plant, and even making a 3D model of the entire plant. The system also allows the linking of documentation, such as plans, photographs, diagrams, manuals, and databases to individual items of equipment and the systems that make up the hydro plant, for easy consultation.

Following the success of the pilot carried out at the El Pintado plant, Endesa has extended this model to nine other plants. These are Tajo de la Encantada and Guillena in Andalusia, Eume and Moncabril in Galici, Peñadrada in Castilla y León, plus Canelles, Sallente, Moralets and Serós in Catalonia.

As Dominguez explained: “We have not only developed the digital twin in order to have a 360 view of the installations, we have also launched a diagnostic digital twin that receives more than 6000 analogue measurements in real time, including temperature, pressure, speed, vibration, etc, which are used to predict future values. These models are adjusted taking into account the normal behaviour of the equipment and they alert us when the values received in real time do not match the estimated values.”

Endesa currently has digital twin diagnostic models implemented in the 38 largest hydroelectric power plants, which cover nearly 70% of all installed capacity. There is ongoing monitoring of the main and the most critical equipment and, at the same time it is remotely displayed for operation and maintenance specialists.

Monitoring and inspections

Accessibility to dam sites can be problematic when monitoring and inspections are required. At New Bullards Dam in California’s Yuba Valley in the US, surveyors had to endure a treacherous and time-consuming hike to reach the facility. It not only took a week for the return journey, carry out the surveys and then process the data once back safely in the office, it was also a safety hazard that exposed personnel to challenging conditions and necessitated additional training in rope access and fall protection in high-risk locations. In addition, limited survey points across this 197m high and 700m wide double curvature arch dam meant that it couldn’t be fully monitored.

Eventually dam safety engineers at Yuba Water Agency began to think about alternatives, especially as they’d seen other dam operators looking into digital twins for their facilities. However Yuba Water Agency wasn’t sure if it was possible as they’d only seen them used on embankment dams, and didn’t know of any on such a vertical structure as theirs, which is the second tallest dam in California and the fifth tallest in the US.

However, Bentley Systems came to the rescue and installed its iTwin Capture digital twin software system that created a 3D reality mesh of New Bullards Bar Dam from thousands of drone captured images. The system was able to cover the entire face of the dam and monitor its movement and behaviour over time under different conditions. In comparison to previous manual data collection, there were one thousand times more monitoring data points which were able to give an up-to-date representation of the facility, and led to a 50% improvement in data accuracy.

As digital twins look set to become the norm in the dams industry, they may well lead to less reliance on inspection methods that can often require extensive scaffolding in high risk areas and expose workers to safety hazards, and may even provide a solution to the shortage of skilled workers that is encompassing the global industry.