In the monitoring and management of tailings dams and levees, it is common practice to employ two primary methods: internal monitoring and external monitoring. Internal monitoring involves the assessment of deformations, loads, and pore pressures within the structure itself, providing insights into its structural integrity and stability. External monitoring focuses on detecting deformations and leaks on the surface or outer border of the dam, offering valuable information about the overall condition and potential risks.

The integration of both internal and external monitoring approaches is essential for a thorough risk management strategy. While external monitoring is undoubtedly significant in detecting visible signs of distress or deterioration, such as surface cracks or seepage, internal monitoring plays a vital role in identifying subtle changes and early indicators of potential failures that may not be immediately visible.

By assessing factors like deformations and pore pressures, proper internal and external monitoring initiatives provide early warning signs, allowing dam safety personnel to intervene and implement strategies before a critical failure occurs.

Instrumentation and data

Various types of instrumentation can be deployed to collect data for monitoring tailings dams. For example, in-place inclinometers allow measurement of internal structural deformation and identification of internal failures and are used to measure slope stability by monitoring changes in the tilt of the dam structure. Piezometers can be installed to measure pore water pressure, providing crucial information on the dam’s saturation.

Load cells can be installed to assess the structural integrity of the dam by measuring the distribution of forces acting upon it. Settlement gauges track any subsidence or settlement of the dam structure over time. Seepage metres help in evaluating the flow of water through the dam, aiding in the detection of potential leaks or weaknesses.

Additionally, GPS systems are used for geospatial monitoring, allowing for precise tracking of the dam’s position and any movement over time. Remote sensing techniques, such as LiDAR (Light Detection and Ranging), can be employed to generate detailed 3D models of the dam and its surroundings. These models provide valuable information into the topography and structural integrity of the dam, aiding in risk assessment and planning.

By employing a combination of these instrumentation methods, mining personnel can gain a full understanding of the behavior and condition of tailings dams. This holistic approach to monitoring enables proactive risk management and maintenance efforts, ultimately enhancing the safety and stability of such structures.

Data integration with MLSuite

With the ability to ingest data from a multitude of sources –including remote sensing devices, instrumentation and dataloggers from most vendors – MLSuite is a comprehensive data integration platform that offers users the ability to automate their tailings monitoring processes, enhance decision-making, and optimise operations, leading to heightened efficiency and cost savings.

The platform seamlessly integrates various instrument data into a unified view. This consolidation allows for convenient access and streamlined analysis of data for optimal insights.

MLSuite features a programmable interface, enabling users to schedule data collections from numerous devices effortlessly. Its adaptable database, file, scripting, and API import capabilities empower users to connect unique data sources effectively. Additionally, its integrated GIS engine simplifies the georeferencing of data, events, and locations, offering seamless integration and accessibility.

MLWeb stands as the web-based visualisation component within MLSuite. Within MLWeb, users can explore and interact with data in a seamless, web-based environment. This component offers a range of powerful visualisation tools tailored to meet diverse tailings monitoring data analysis and integration needs.

Designed with user convenience in mind, MLWeb provides intuitive features that facilitate efficient data exploration and analysis. Whether it’s examining trends, or identifying patterns through custom charts and reports, MLWeb empowers users to delve into their data with ease.

Moreover, MLWeb’ s web-based nature ensures accessibility across various devices and platforms, allowing users of all levels to view and analyse data anytime, anywhere. This flexibility enhances collaboration and decision-making processes by enabling users to engage with data in near real-time.

Nevada mining

In the heart of Nevada’s mining landscape lies an operation that handles more than 30,000 tons of gold ore daily, sourced from both open-pit and underground sites. With such significant throughput comes the responsibility of managing the resulting materials efficiently and safely. To meet this challenge, the mine relies on a tailings storage facility, boasting one of the world’s largest rockfill tailings dams. To ensure the integrity and stability of this critical structure, the mine partnered with Canary Systems.

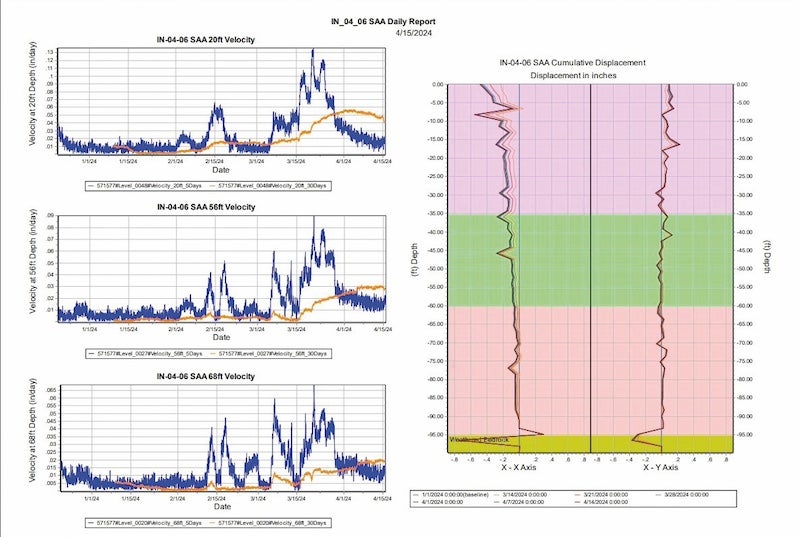

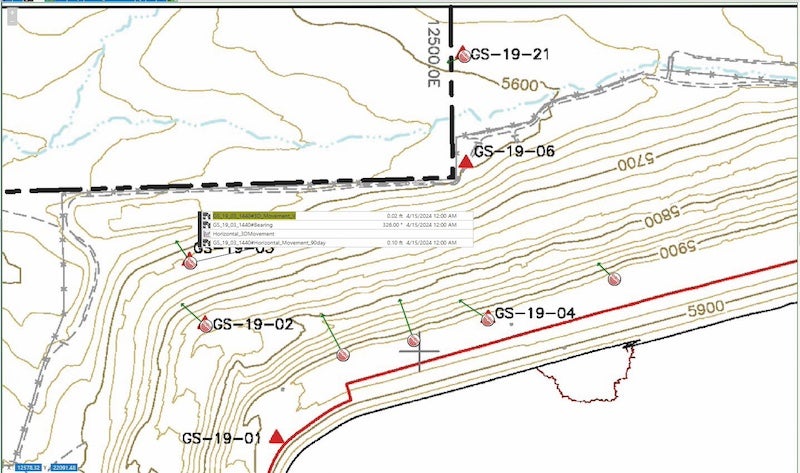

Canary Systems deployed and integrated a suite of instruments. Piezometers were strategically installed to measure pore water pressure within the dam. Multiple MLGPS systems were deployed to precisely track ground movement and deformation, offering invaluable data for assessing stability. Shape Array Accelerometers (SAAs) were integrated to detect and monitor any structural vibrations or deformations. Additionally, thermistors and thermocouples were implemented to monitor temperature variations.

MLWeb empowers the mine’s personnel to visualise monitoring data in near real-time and generate insightful charts and graphs for trend analysis. The movement of ground vectors from the MLGPS systems is accurately depicted, providing a clear understanding of any shifting patterns or trends. Moreover, using Canary Systems’ calculation engine, displacement velocities are calculated for the SAAs, enabling the detection of structural deformations and facilitating proactive maintenance measures. This advanced functionality enhances the mine’s ability to detect potential risks and implement timely interventions to monitor and assess the integrity of the tailings dam.

By effectively deploying monitoring instruments and seamlessly integrating them with the MLSuite platform, the mine has substantially improved its capacity to oversee and regulate the stability of its tailings storage facility. Access to extensive monitoring data, complemented by customized alarm notifications, facilitates proactive decision-making, thereby reducing risks and maintaining the ongoing safety of the site for years to come.