From population growth and technological advancements to increasing industrialisation, the global demand for energy has been steadily rising since the 1950s. Unlike in the past, we now understand that oil, coal, and gas are not sustainable solutions to meet this demand. To make the transition to renewable energy a success, we can rely on a proven foundation since decades: hydropower.

From hidden champion to protagonist of the energy transition

The role of hydropower has evolved over the years. Once a hidden champion that unobtrusively secured the baseload energy supply for entire nations, it is now a cornerstone of the future energy mix. Hydropower is not only the leading supplier of renewable energy, but it is also the only sustainable and reliable method to counterbalance the variations caused by the intermittent nature of other renewable energies such as wind and solar.

This shift has also redirected the priorities for manufacturers of hydropower technology. There remains substantial potential for new large-scale projects globally. These continue to play a significant role in the economic development of entire regions, as evidenced by Voith’s expanding operations in Africa for example. However aging assets and new requirements towards hydropower shift, the focus increasingly turning towards modernisation and service.

The time has come to modernise existing hydropower plants

At present, a wave of extensive modernisation is sweeping across numerous significant facilities worldwide. These include Porto Colombia and Paulo Afonso in South America, Fort Randall and Norfolk in the US, or Foyers and Gerlos in Europe, to name a few. These systems aren’t just upgraded with new components; the modernisation process itself benefits from cutting-edge technologies.

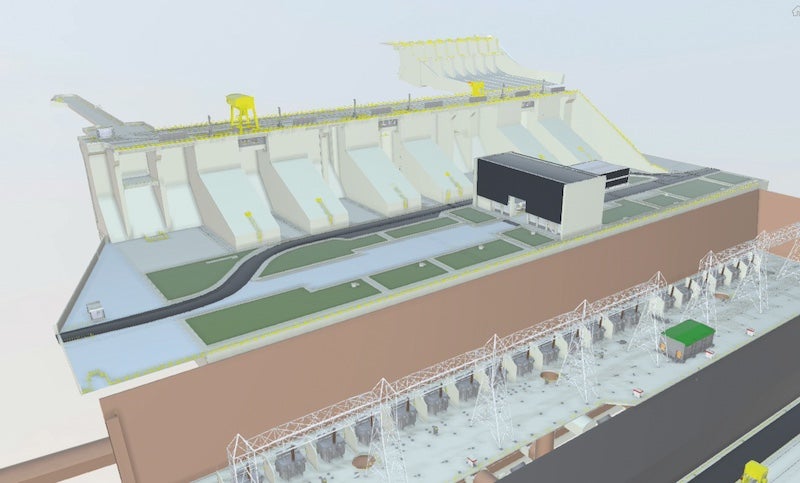

Take Building Information Modeling (BIM), for instance. BIM enables digital capture, management, and visualisation of system information, facilitating both modernisation and maintenance. These modernisation initiatives are of paramount importance, especially in the context of sustainable and secure energy supply. They ensure the reliable operation of these facilities while also upgrading the hydropower capacities to meet the evolving demands of renewable power generation.

Consequently, these plants enhance grid stability and bolster the security of supply. Environmental considerations, such as sediment management solutions and retrofitting for fish protection, are also gaining importance.

In line with this, the design of hydropower plants is being progressively optimised to cater to the emerging needs of the energy transition. The goal is to empower operators to better handle rapid load fluctuations and manage a higher frequency of starts and stops. Voith is spearheading initiatives such as the Francis+ project. It aims to enable the systems to operate unrestrictedly in the partial load range, in addition to improving energy efficiency and reducing maintenance costs.

Competent service is becoming increasingly important

The pivotal role of hydropower in the system amplifies the significance of plant maintenance and servicing. The need for reliable, uninterrupted operation throughout the year is more critical than ever. Consequently, operators require seasoned service partners in their vicinity who can offer competent and reliable support around the clock. This ensures the safe, efficient, and maximum availability of their systems throughout their entire lifecycle and beyond. To facilitate this, Voith is progressively focusing on expanding its services. Customers can rest assured that experienced service teams are always within reach to provide swift assistance in case of unforeseen issues.

Ideally, the service is designed to prevent such problems from occurring in the first place. Presently and in the future, two resources can significantly enhance longer runtimes, greater reliability, and superior performance: digital solutions and dedicated teams.

Intelligent solutions for hydropower plants

Thanks to automation, the majority of hydropower plants are already poised to embrace a more digital future. Digital solutions serve to enhance the operation of hydropower plants at various levels. Monitoring, analysis, and diagnostic systems pave the way for early fault detection and condition-based maintenance. These systems facilitate the planning and execution of preventive maintenance measures, significantly cutting down operating and maintenance costs, and potentially averting shutdowns altogether. Moreover, interactive applications enable integration into the overall asset management of a system and foster direct communication with service experts.

Hydro Pocket is an example of how digitalisation is also advancing in pocket format and even for small hydro. The app is an intuitive, simple, cloud-based application that allows plant owners and operators to monitor, analyse and optimise hydropower stations.

Looking ahead, artificial intelligence (AI) will equip operators with an even broader and more precise toolkit to make hydropower utilization more reliable and efficient. New assistance systems can aid in making plant documentation searchable for specific problem solutions. Algorithms can pinpoint deviations with greater accuracy and reveal previously unknown correlations. Operating data can be correlated with environmental, weather, and other data to prevent accidents or breakdowns and to unlock new performance potential.

People make the difference

However, digital technologies and AI are merely supplementary forces that can, at best, aid the true champions of hydropower utilization: the individuals who, with remarkable personal dedication, passionately propel these projects forward across the globe. Many have devoted their lives to the cause of hydropower, with some even passing on this dedication to their families, so that their descendants are working on the same projects. Some possess a unique understanding of their machines, a knowledge that is growing increasingly invaluable.

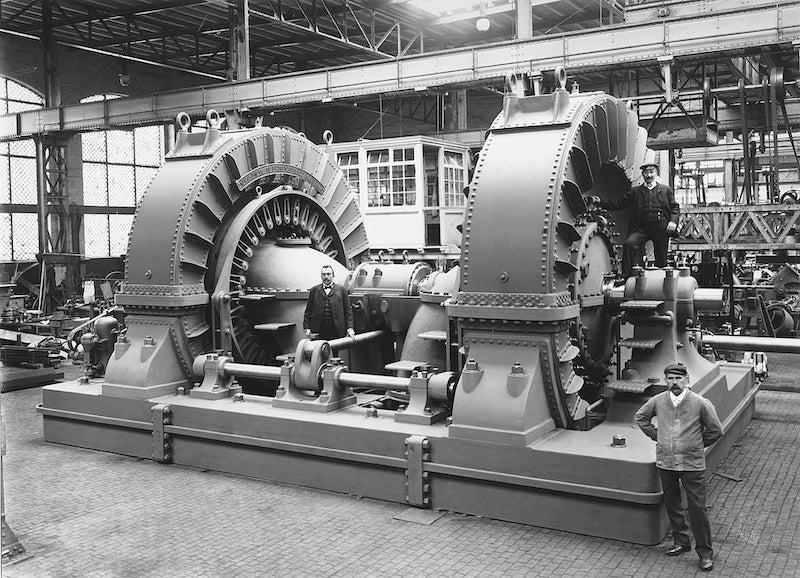

For over 150 years, Voith has been dedicated to developing and optimising this crucial element of the renewable energy mix as a comprehensive service provider. Since manufacturing its first turbine in 1870, Voith has made significant strides in the international hydropower market with its expertise and innovative capabilities.

From supplying twelve turbines to the Ontario Power Company at Niagara Falls at the start of the 20th century to partnering in numerous significant projects worldwide – such as in Itaipú or at the Three Gorges Dam – Voith has played a significant role. This remarkable achievement owes its gratitude to the exceptional people behind hydropower.

In the face of the global climate crisis, the contributions of these individuals are immeasurable. They are all tirelessly working in what can be termed as the energy engine room of the future, since generations: Making renewable energy reliable.

There is no task more significant.